VS Dyes VS Dyes |

Product | Yellow - 7GL | Yellow - 4GL | Yellow - GL | Yellow - FG | Yellow - GR | Golden Yellow- RNL | Golden Yellow- R | Yellow - 3RS(133%) | Orange - 2R | Orange - 3R | Red - C2G | Red - 5B | Red - 3B | Red - 3BS | Red - RB | Red - RBN | Red - RBL | Red - BRS | Violet - 5R | Brown - GR | Turg.Blue - G(133%) | Turq.Blue H2GP | Green - 6B | Blue - BB (133%) | Blue - R | Blue - 3R | Dark Blue - HR | Black B | Black - BC | Navy Blue - 2G | Black - RL | Deep Black-N-150 | Deep Black-N-200 | |

| C.i. No. | Yellow - 57A | Yellow - 160A | Yellow - 37 | Yellow - 42 | Yellow - 15 | Orange - 107 | Own Shade | Yellow - 176 | Orange - 7 | Orange - 16 | Red - 106 | Red - 35 | Red - 23 | Red - 239 | Red - 198 | Own Shade | Red - 198A | Red - 111 | Violet - 5 | Brown - 18 | Blue - 21 | Blue - 77 | Blue - 38 | Blue - 220 | Blue - 19 | Blue - 28 | Blue - 89 | Black - 5 | Black - 5 Redder | Blue - 203 | Black - 31 | Black - Mix | Black - Mix | ||

| 10 G/L Shade |

|||||||||||||||||||||||||||||||||||

| 40 G/L Shade |

|||||||||||||||||||||||||||||||||||

| 4% Print | |||||||||||||||||||||||||||||||||||

| Discharge Printing | |||||||||||||||||||||||||||||||||||

| Solubility in DM Water (Grams/Lit.) (At 30°C Temperature) |

80 | 80 | 80 | 80 | 80 | 80 | 80 | 150 | 60 | 60 | 60 | 60 | 100 | 200 | 100 | 200 | 100 | 200 | 80 | 50 | 80 | 80 | 80 | 80 | 150 | 80 | 80 | 100 | 100 | 100 | 80 | 100 | 100 | ||

| Solubility with 60 G/L Salt (Grams/Lit.) (At 30°C Temperature) |

55 | 40 | 40 | 50 | 45 | 55 | 55 | 100 | 45 | 35 | 40 | 40 | 40 | 120 | 65 | 110 | 65 | 110 | 60 | 35 | 50 | 50 | 50 | 50 | 105 | 60 | 55 | 80 | 80 | 60 | 50 | 80 | 80 | ||

| Light Fastness (1-8 Gray Scale Rating) (ISO - 105 - B02) |

5 G/L Depth | 5-6 | 4 | 4-5 | 4 | 4.5 | 4 | 5 | 4-5 | 4 | 4-5 | 3 | 3 | 3-4 | 4-5 | 3-4 | 3-4 | 3-4 | 3-4 | 5 | 5 | 4-5 | 4-5 | 4-5 | 5 | 4-5 | 4-5 | 3 | 3 | 3 | 2-3 | 3-4 | 3-4 | 3-4 | |

| 30 G/L - Depth | 6-7 | 5 | 6 | 5 | 6 | 5 | 6 | 6 | 5 | 5-6 | 4 | 4 | 5 | 5-6 | 5 | 4-5 | 4-5 | 4-5 | 6-7 | 6 | 6 | 6 | 6 | 6-7 | 6-7 | 6-7 | 4-5 | 5 | 5 | 4 | 6-7 | 4-5 | 4-5 | ||

| Washing Fastness (ISO - 105 - C03 Method) (60°C - 30') (5 g/l Soap + 3 g/l Soda) |

10 G/L Depth | Effect | 5 | 4 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 5 | 5 | 4-5 | 4-5 | 4 | 4-5 | 4 | 5 | 5 | 4 | 4 | 4 | 5 | 4-5 | 5 | 4 | 4-5 | 4-5 | 4-5 | 4 | 4-5 | 4-5 |

| Stain | 4-5 | 4 | 4-5 | 4-5 | 4-5 | 4-5 | 4 | 4 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4 | 4 | 4 | 4 | 4 | 5 | 5 | 4 | 4 | 3-4 | 4-5 | 4-5 | 4-5 | 3 | 4-5 | 4-5 | 4-5 | 4 | 4-5 | 4-5 | ||

| 40 G/L Depth | Effect | 4 | 4 | 4-5 | 4-5 | 4-5 | 4 | 4 | 4 | 4 | 4 | 4 | 4-5 | 4-5 | 4-5 | 4 | 4 | 4 | 4 | 4 | 4-5 | 3-4 | 3-4 | 3-4 | 4-5 | 4 | 4 | 3 | 4 | 4 | 3-4 | 4 | 4 | 4 | |

| Stain | 4 | 4 | 4 | 4 | 4 | 4 | 3-4 | 3-4 | 3-4 | 4 | 3-4 | 4 | 3-4 | 3-4 | 3-4 | 3 | 3-4 | 3 | 4 | 4 | 2-3 | 2-3 | 2-3 | 4-5 | 3-4 | 4 | 2-3 | 3-4 | 3-4 | 3 | 3-4 | 3-4 | 3-4 | ||

| Rubbing Fastness (ISO - 105 - X12 Method) (10 Strokes-To & Fro) (Crock meter) |

10 G/L Depth | Dry | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 4-5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 4-5 | 4-5 | 4-5 | 5 | 5 | 5 | 4-5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Wet | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4-5 | 3-4 | 4 | 3-4 | 4-5 | 4-5 | 3-4 | 4 | 4 | 4-5 | 4 | 4-5 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | ||

| 40 G/L Depth | Dry | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4 | 4 | 4 | 4-5 | 4-5 | 4-5 | 4 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | |

| Wet | 4 | 4 | 4 | 4 | 4 | 3-4 | 3-4 | 3-4 | 3-4 | 3-4 | 3-4 | 3 | 3-4 | 3-4 | 4 | 3 | 3-4 | 3 | 4 | 4 | 3 | 3-4 | 3-4 | 4 | 3-4 | 4 | 3 | 3-4 | 3-4 | 3-4 | 3-4 | 3 | 3 | ||

| Perspiration Fastness Acidic - pH - 5.5 (ISO - 105 - E04) (37° C Temp - 4 hrs) |

40 G/L Depth | Effect | 4-5 | 5 | 4 | 4 | 5 | 4-5 | 5 | 4-5 | 4-5 | 4-5 | 5 | 4 | 4 | 4 | 4-5 | 4-5 | 4-5 | 4-5 | 4 | 4 | 4 | 4 | 4 | 5 | 4 | 4 | 4 | 5 | 5 | 4 | 5 | 5 | 5 |

| Stain | 4-5 | 5 | 4 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4 | 4 | 4-5 | 4-5 | 4 | 5 | 4 | 4-5 | 4-5 | 4-5 | 4 | 4-5 | 5 | 4 | 4 | 4 | 4 | 4 | 4-5 | 4 | 4 | ||

| Perspiration Fastness Alkaline - pH 8.0 (ISO - 105 - E04) (37° C Temp - 4 hrs) |

40 G/L Depth | Effect | 4-5 | 4 | 4 | 4 | 5 | 4-5 | 4 | 4-5 | 5 | 5 | 5 | 5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 3-4 | 4 | 4 | 4 | 4 | 5 | 4 | 4 | 4 | 5 | 5 | 4 | 4-5 | 5 | 5 |

| Stain | 4-5 | 5 | 4 | 4-5 | 5 | 4-5 | 4 | 4-5 | 5 | 5 | 4-5 | 5 | 4-5 | 4-5 | 4-5 | 4-5 | 4 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4 | 4 | 5 | 4 | 4 | 4 | 4 | 4 | 4-5 | 4 | 4 | ||

| Chlorinated Water Fastness (ISO -105 - E03) (20 ppm) (27° C Temp -1 hr) |

40 G/L Depth | Effect | 3-4 | 3 | 2-3 | 1 | 1 | 2-3 | 1 | 3-4 | 4 | 4 | 2 | 4 | 3 | 4 | 2-3 | 2-3 | 3 | 2-3 | 4-5 | 1 | 2-3 | 2-3 | 4 | 4 | 3-4 | 3-4 | 2-3 | 4 | 4 | 3-4 | 2 | 3 | 3 |

| Stain | 5 | 5 | 5 | 4-5 | 4-5 | 5 | 4-5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 3-4 | 4-5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 4-5 | 5 | 5 | ||

| Depth Of Shade | Salt Ash Reqirement (Grams/Lit.) | Soda Ash Reqirement (Grams/Lit.) | |

| Unmercerised Cotton | Mercerised Cotton or Rayon | ||

|---|---|---|---|

| Up to 0.50% | 25 | 15-20 | 10 |

| 0.51% - 2.00% | 30-40 | 25-40 | 15 |

| 2.1% - 4.00% | 50 | 45 | 20 |

| Above 4% | 60-80 | 50-70 | 20 |

Application process sequence chart for Jiger Dyeing Machine

| Add half amount of Dyestuff | Run One End |

| Add remaining amount of Dyestuff | Run One End |

| Add half amount of Salt | Run Three End |

| Add half amount of Alkali | Run One End |

| Add remaining amount of Alkali | Run Four End or More if Required |

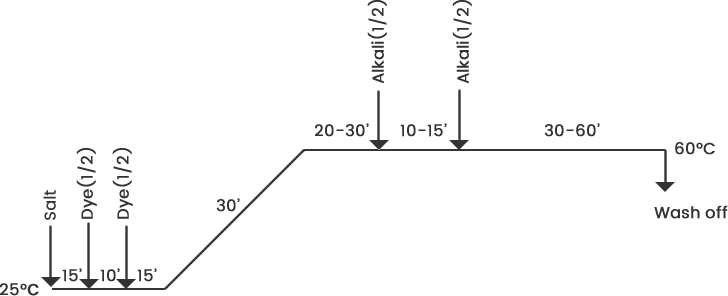

Application process sequence chart for winch, jet, Package, Beam Dyeing Machines

| 01 | Reactron ' VS ' Dyestuff | X Grams |

| 02 | Urea | 60-100 Grams |

| 03 | Sodium Alginate | 20-30 Grams |

| 04 | Resist Salt | 10 Grams |

| 05 | Soda bi carb | 2-3- Grams |

| 05 | Water | Balance |

| Total | 1000 Grams |

Print through above printing paste

Dry the print

Steam with saturated steam at 1050 -1100 C temperature (or 8 -13 minutes

Wash the print as per the sequence given below

Dry the print

| 01 | Reactron ' VS ' Dyestuff | X Grams |

| 02 | Urea | 10-40 Grams |

| 03 | Sodium Alginate | 20-30 Grams |

| 04 | Resist Salt | 10 Grams |

| 05 | Water | Balance |

| Total | 1000 Grams |

print through above printining paste

Dry the print

Pad through 100 - 110° TW Sodium Silicate solution containing 4-6 cc/l Caustic Soda 32.5%

Cover with plastic sheet

Batch for 16-24 hours

Wah the print as per the sequence given below

Dry the print

| 01 | Reactron ' VS ' Dyestuff | X Grams |

| 02 | Urea | 60-100 Grams |

| 03 | Sodium Alginate & Caustic Soda Solution | As per table given below |

| 04 | Wetting Agent | 1 - 3 Grams |

| 05 | Water | Balance |

| Total | 1000 Grams |

| Silicate Grade Be / Tw | Weight Ratio Na20 : Si02 | Qty. of Silicate ( g / l) | Qty of Caustic Slution (32.5%) | |

|---|---|---|---|---|

| Upto 30 g/l | Above 30 g/l | |||

| 37-40 / 69-77 | 1:3.3 | 135 | 13 | 18 |

| 40-42 / 77-82 | 1:3.3 | 120 | 11 | 16 |

| 48-50 / 100-106 | 1:2.6 | 100 | 5 | 10 |

| 58-60 / 134-142 | 1:2.1 | 85 | - | 4 |

| Silicate Grade Be / Tw | Weight Ratio Na20 : Si02 | Qty. of Silicate ( g / l) | Qty of Caustic Slution (32.5%) | |||||

|---|---|---|---|---|---|---|---|---|

| 20 g/l | 30 g/l | 40 g/l | 50 g/l | 60 g/l | 70-100 g/l | |||

| 37-40 / 69-77 | 1:3.3 | 130 | 23.5 | 28.5 | 28.5 | 33.5 | 33.5 | 38.5 |

| 40-42 / 77-82 | 1:3.3 | 110 | 25 | 30 | 30 | 35.0 | 35.0 | 40.0 |

| 48-50 / 100-106 | 1:2.6 | 100 | 15 | 20 | 20 | 25.0 | 25.0 | 30.0 |

| 58-60 / 134-142 | 1:2.1 | 90 | 6.5 | 11.5 | 11.5 | 16.5 | 16.5 | 21.5 |

Dissolve dyestuff pouring boiling water.Cool at 45°C temp. Add Urea. Add Sodium Silicate & Caustic Soda solution just before padding. Pad the fabric at 60%-70% expression for cotton and 90% for viscose fabric. Cover the fabric with plastic sheet and allow to dwell for 16-24 hours for long term method and 5-10 hours for short term method. Then wash as per the washing sequence given below.

| 01 | Reactron ' VS ' Dyestuff | X Grams |

| 02 | Urea | 60-100 Grams |

| 03 | Resist salt | 10 Grams |

| 04 | Soda Ash | 6 - 12 Grams |

| 05 | Wetting Agent | 1-3 Grams |

| 05 | Water | Balance |

| Total | 1000 Grams |

Dissolve dyestuff pouring boiling water.Cool at 45°C temp. Add Urea. Add Resist Salt and Wetting Agent. Add Soda Ash solution just before padding. Pad the fabric at 60%-70% expression for cotton and 90% for viscose fabric. Dry the fabric. Steam the fabric in continuous steamer for 7-10 minutes at 100-105°C temperature and then wash.

| 01 | Reactron ' VS ' Dyestuff | X Grams |

| 02 | Urea | 60-100 Grams |

| 03 | Resist salt | 10 Grams |

| 04 | Soda Ash | 12 - 30 Grams |

| 05 | Wetting Agent | 1-3 Grams |

| 05 | Water | Balance |

| Total | 1000 Grams |

Dissolve dyestuff by pouring boiling water. Cool at 45°C temp. Add Urea. Add Resist Salt and Wetting Agent. Add Soda Ash solution just before padding. Pad the fabric at 60%-70% expression for cotton and 90% for viscose fabric. Dry the fabric as recommended in below table during which time fixation also take and the wash.

| Drying Temp. (°C) | Drying Time(Min.) |

|---|---|

| 100 | 6-8 |

| 110 | 4-5 |

| 120 | 3-4 |

| 130 | 2-3 |

| 140 | 1.5-2 |

| 01 | Thickener | 500 Grams |

| 02 | Rongolite C | 250-200 Grams |

| 03 | Titanium Dioxide (1:1) | 100 Grams |

| 04 | Caustic Soda 72°TW | 100 - 200 Grams |

| 05 | Water | Balance |

| Total | 1000 Grams |

| 01 | Starch Paste | 100 Grams |

| 02 | Citric Acid | 60-100 Grams |

| 03 | Optical Brightener(Resistant to Acid) | 10 Grams |

| 04 | Thickening | 500 Grams |

| 05 | Water | Balance |

| Total | 1000 Grams |

Print → Dry → through dye solution prepared as per below table:

| 01 | Reactron ' VS ' Dyestuff | X Grams |

| 02 | Urea | 150-200 Grams |

| 03 | Reasist Salt | 10 Grams |

| 04 | Sodium Bi-Carbonate | 250-300 Grams |

| 05 | Water | Balance |

| Total | 1000 Grams |

Pad the fabric

Dry the fabric

Steem the fabric in continuous steamer for 5 - 7 minutes at 100-105° C temp and then wash as per the washing sequence given below.