XF dyestuff XF dyestuff |

Product | Lemon Yellow 3GXF | Yellow 3RXF | Orange 2RXF | Red 3BXF | Dark Red 5BXF | Scarlet 2GXF | Rubine CRXF | Cherry Red ORXF | T. Blue CBXF | Dark Blue 2BXF |

Sapphire Blue BRXF |

Royal Blue SRXF |

Black BRXF |

Deep Black RGXF | Night Black OBXF | |

| 1% Shade | |||||||||||||||||

| 4% Shade | |||||||||||||||||

| Solubility in DM Water (Grams/Lit.) (At 30°C Temperature) |

80 | 130 | 40 | 200 | 30 | 60 | 100 | 130 | 80 | 70 | 60 | 80 | 100 | 100 | 100 | ||

| Solubility with 60 G/L Salt (Grams/Lit.) (At 30°C Temperature) |

50 | 70 | 20 | 100 | 10 | 20 | 50 | 60 | 40 | 20 | 20 | 40 | 60 | 45 | 40 | ||

| Light Fastness (1-8 Gray Scale Rating) (ISO-105-B02) |

0.5% Depth | 4-5 | 4-5 | 3-4 | 4 | 4 | 3-4 | 3-4 | 3-4 | 4 | 4 | 4 | 4-5 | 3-4 | 3-4 | 3-4 | |

| 3.0% Depth | 5 | 5-6 | 4-5 | 5 | 4-5 | 4-5 | 4-5 | 4-5 | 5-6 | 5 | 5-6 | 5-6 | 4 | 4 | 4 | ||

| Washing Fastness (ISO-105-C03 Method) (60°C - 30') 5 g/l Soap + 2 g/I Soda MLR 1:50 |

1% Depth | Effect | 5 | 5 | 5 | 5 | 4-5 | 5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 5 | 4-5 | 4-5 |

| Stain | 5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4 | 4 | 4 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | ||

| 4% Depth | Effect | 4-5 R |

4-5 | 4 | 4-5 | 4 | 4-5 | 4-5 | 4 | 3-4 | 4 | 4 | 4 | 4-5 | 4 | 4 | |

| Stain | 4-5 | 4 | 4 | 4 | 3-4 | 3-4 | 3-4 | 3-4 | 3 | 3-4 | 3-4 | 4 | 4 | 3-4 | 3-4 | ||

| Rubbing Fastness (ISO -105-X12 Method) (10 Strokes-To & Fro) (Crock meter) |

1% Depth | Dry | 5 | 5 | 5 | 4-5 | 4-5 | 5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 |

| Wet | 4-5 | 4-5 | 4-5 | 4 | 3-4 | 4-5 | 4 | 4 | 4 | 4 | 4 | 4 | 4-5 | 4 | 4 | ||

| 4%Shade - | Dry | 4-5 | 4-5 | 4-5 | 4 | 4 | 4-5 | 4 | 4 | 4 | 4 | 4 | 4-5 | 4 | 4 | 4 | |

| Wet | 4 | 4 | 3-4 | 3-4 | 3 | 3-4 | 3 | 3-4 | 3 | 3-4 | 3-4 | 3-4 | 3-4 | 3 | 3 | ||

| Perspiration Fastness Acidic - pH -5.5 MLR 1:50 (ISO-105-E04) (37° C Temp - 4 hrs) |

4%Shade - | Effect | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4 | 4 | 4-5 | 4 | 4 |

| Stain | 4-5 | 4 | 4-5 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4-5 | 4-5 | 4 | 4 | ||

| Perspiration Fastness Alkaline - pH 8.0 MLR 1:50 (ISO-105-E04) (37° C Temp - 4 hrs) |

4% Shade - | Effect | 4 R |

4-5 | 4-5 R |

4-5 | 4 | 4 | 4-5 | 4-5 | 4 | 4-5 | 4 | 4 | 4-5 | 4 | 4 |

| Stain | 4-5 | 4 | 4-5 | 4 | 4 | 4 | 4 | 4 | 3-4 | 3-4 | 3-4 | 4 | 4 | 3-4 | 3-4 | ||

| Chlorinated Water Fastness (ISO-105-E03) MLR 1:100 (20 ppm available chlorine) (27° C Temp -1 hr) |

4%Shade | Effect | 3 | 3 | 3-4 | 3-4 | 3-4 | 2-3 | 3 | 3 | 2-3 | 2-3 | 2-3 | 3 | 3 | 2-3 | 2-3 |

| Stain | 4-5 | 4 | 3 | 4 | 3 | 3-4 | 3-4 | 4 | 3-4 | 3-4 | 3 | 3-4 | 3-4 | 3 | 3 | ||

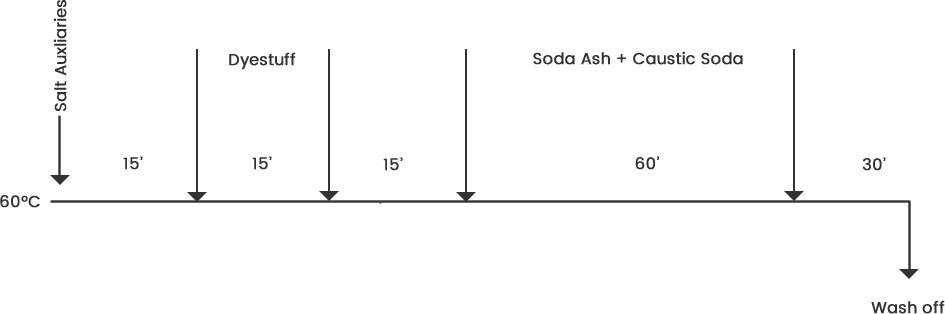

Maintain the dye bath at minimum of 60°C - 65°C temperature during the addition of salt.

Adjust the dye bath temperature at 60°C - 65°C temperature to ensure that fabric is maintained at minimum 60°C temperature during alkali addition stage.

Batch the fabric evenly

Recommendation of salt & alkali requirement as per details given on next flap.

Set the dye batch at 60°C temperature

| Add half amount of Dyestuff | Run One End |

| Add remaining amount of Dyestuff | Run One End |

| Add half amount of Salt | Run One End |

| Add remaining amount of Salt | Run Three End |

| Add half amount of Alkali | Run Three End |

| Add remaining amount of Alkali | Run Four End or More if Required |

| Depth Of Shade | Salt Requirement (Grams/Lit.) | Soada Ash Requirment (Grams/Lit.) |

|---|---|---|

| Up to 0.50% | 20 | 10 |

| 0.5% - 1.0% | 20 - 40 | 15 |

| 1.0% - 3.0% | 40 - 60 | 20 |

| 3.0% - 5.0% | 60 - 80 | 20 |

| 5.0% - 7.0% | 80 - 90 | 20 |

| Depth Of Shade | Salt Requirement (Grams/Lit.) | Soada Ash (Grams/Lit.) | Caustic Flakes(Grams/Lit.) |

|---|---|---|---|

| Up to 0.50% | 20 | 5 | 0.00 - 0.35 |

| 0.5% - 1.0% | 20 - 40 | 5 | 0.35-0.45 |

| 1.0% - 3.0% | 40 - 60 | 5 | 0.45 - 0.75 |

| 3.0% - 5.0% | 60 - 80 | 5 | 0.75 - 1.00 |

| 5.0% - 7.0% | 80 - 90 | 5 | 1.00 |

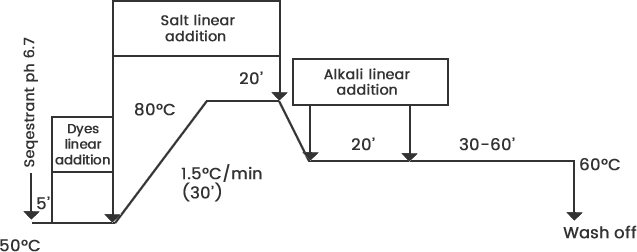

This method is recommended for machines with microprocessor controlled addition system for dying pale shades(less then 0.5% depth) and for all shades on merecerised cotton & viscose packages.